DELTA minimizes dirt

Foreign material defects are the number #1 cause for poor paint quality in high production painting lines. Foreign material, collectively referred to as dirt, has its origin in many sources. Dried paint overspray, cotton and synthetic fibers, poor filtration, paint carrier debris, and sanding residue are primary causes.

Request a ProposalModules of Technical Cleaning

Minimizing dirt is no easy task. To be sustainable four modules are required:

Technical Cleaning

Over 100 weekly technical cleaning tasks are required in a typical paint line to produce a quality painting environment. Knowledge and experience of paint systems and what drives quality allows the right tasks to be defined and prioritized. This is not enough. The right techniques, materials and frequency are required to be effective.

Air Flow Management

Maintaining proper air flow within the paint system is not only necessary to meet ventilation regulations and LEL limits, but to also remove paint overspray, prevent paint overspray drift, maintain heat within ovens and reduce solvent concentrations. Having the correct initial system air balance is where proper air flow starts. But the real challenge is maintaining the air flow as conditions change. Changes include filter loading, wet or dry scrubber paint build-up, fan build-up, and heat and cooling coil loading.

Continuous Improvement

Continuous improvement is the heart of sustainability and cost reduction. Our technical experts know paint systems, what drives quality and where to look for buried treasure. This helps with pinpointing areas that need to be analyzed in order to uncover problematic areas of the paint process causing defects or higher than expected costs. These areas are carefully scrutinized by employing Kaizen events and other quality tools. The results and other more obvious adjustments are built into the technical cleaning tasks system so we close-the-loop.

Management Tools

Steady wins the race when minimizing dirt, sustainably. With so many tasks to perform at different frequencies, an ongoing dynamic system of accountability is mandatory. Self-reporting on completion of tasks with a customer feedback loop, grading performance, is effective and efficient. Transparency is a must since most of the technical cleaning tasks take place on off shifts. SynergyTV brings our system of accountability to life. This dynamic tool allows the information to be viewed on any device, anywhere.

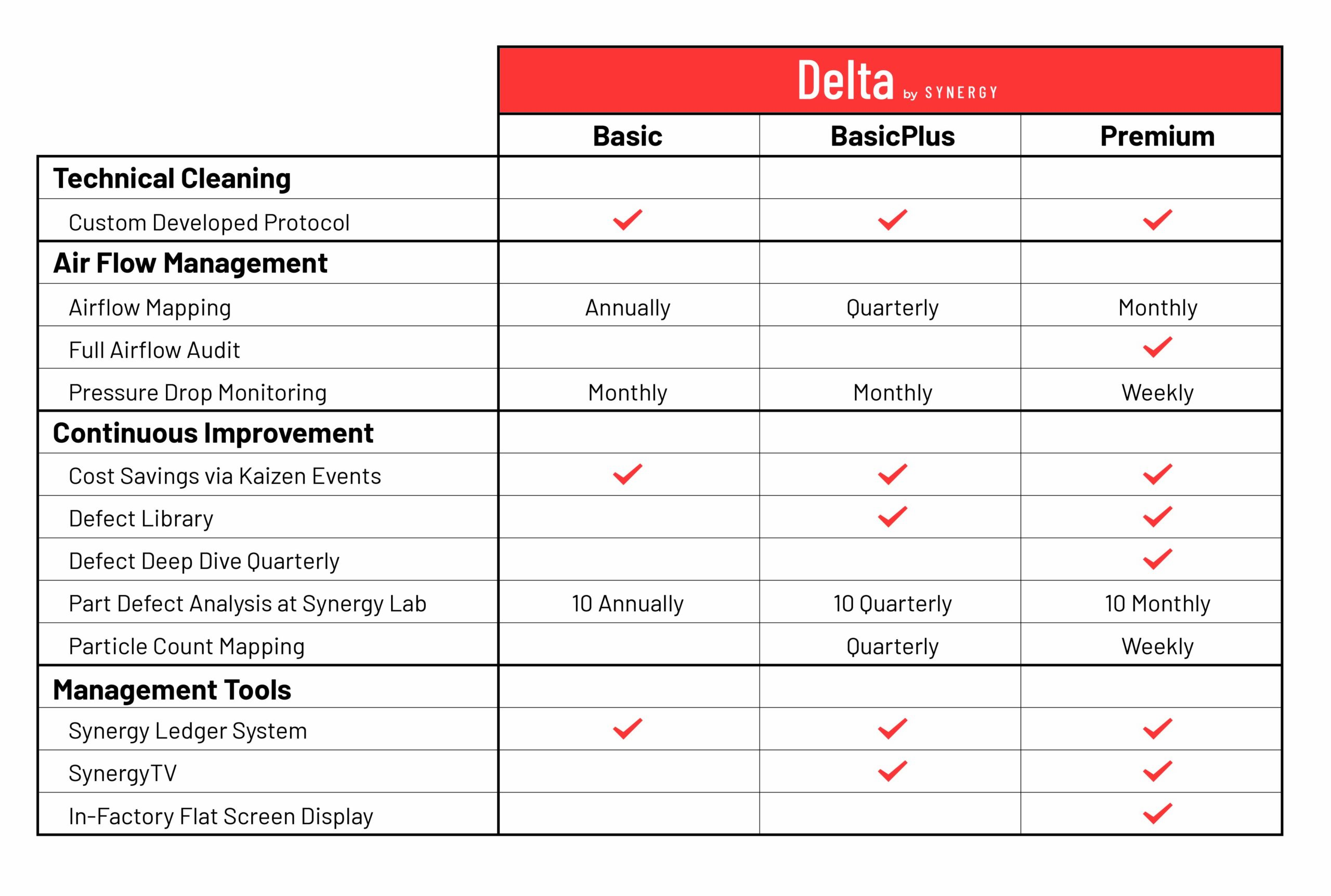

Program Levels:

Program Levels are designed to accommodate different paint shops. The level of production and finish quality demands will guide the decision on which program level is needed.

In general, the higher the production rate and finish quality the higher the program level should be selected. For example, Delta Premium is best for an automotive tier 1 exterior plastics supplier producing parts with a Class A finish and running at a conveyor speed of > 10 FPM.